LANGUAGE

---- Choose the language you like ----

ABOUT US

Quzhou Changheng Industry & Trading company, Professional customization and sales of various industrial machines. Our engineers have worked on average for more than 15 years.

We are more concerned about automotive radiator condenser oil cooler Industrial cooling system manufacturing, Mining machinery and packaging machinery.

What we are most willing to do for our customers is to save money,Since our company was founded, it has helped global customers solve many problems in production and technology.Provide our most advanced production solutions, It is very popular with customers.

OUR SERVICES

From the top technical engineer team in China

transport service

We can transport the machines to any country in the world for our customers.

Training services

We can train new workers for customers and create wealth for your new factory faster.

repair service

Our team can repair all the machines for you , radiator , condenser , oil cooler machines

Custom service

We design professional machines according to the requirements of our customers.

other service

We can find second-hand machines for our customers, its cost performance is very good.

Design services

Our team of technical engineers can design for you Radiator, condenser, intercooler, etc

OUR PRODUCTS

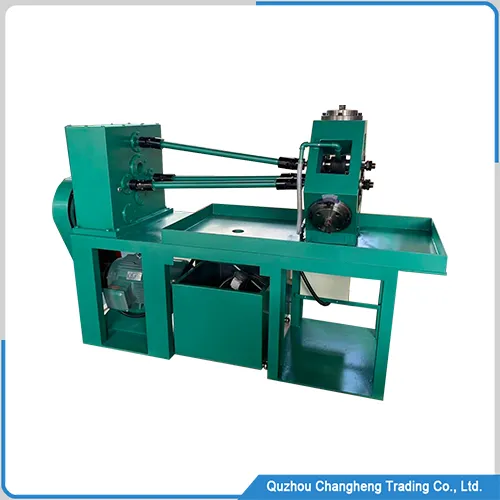

The most cost-effective machine from China

LATEST NEWS

The latest news from the industry

-

07

2024-04

Equipment Overview The Furnace Temperature Logger is a modern temperature monitoring ...

-

31

2024-03

Machine Overview The radiator tube machine realizes the rapid conversion of aluminum ...

-

18

2024-03

Mold Overview The electric motor stamping die plays a crucial role in the motor manuf...

-

17

2024-03

Progressive die Overview This Iron core progressive die for continuous high-speed pro...

-

09

2024-03

Machine Overview This condenser coil bender machine is an efficient automated device ...

-

02

2024-03

Overview The motor core stamping die is a tool specifically designed to manufacture m...

BEST SELLING MACHINES

Our customers' favorite machines

278

Total quantity of our machine projects

99 %

Customer evaluation satisfaction of our service

15 YEAR

Average experience of our engineers

$ 8600000

About our Annual business volume

WHY CHOOSE US

We are far superior to our competitors

cost-effective

lowest price is not our goal,Providing cost-effective products and satisfactory service is the sincere return to customers

One stop shopping

One stop shop for all the machines for your new factory Save time for you

Rich experience

We provide you with the best production solutions, Your every investment will have a high return

Perfect after sales service

Sufficient spare parts supply guarantee, Free customer technical consultation and training,All machines are guaranteed for one year

Professional service team

Our engineers come from the cooling system industry, and their average working experience is more than 15 years,

Quick delivery

We cooperate with the Chinese factory, not only the quality is guaranteed, special machines are available in our warehouse at any time

OUR BUSINESS PARTNERS

Our partners come from more than 30 countries around the world

wechat

wechat