condenser production line outline

The condenser production line is a specialized production line for industrial and automotive condensers,

It adopts advanced automation technology to ensure efficient production and high-quality product output.

Our condenser production line can be adapted to a variety of models and specifications and is well-recognized by the market. Our professional team will provide you with an integrated solution from production planning to after-sales service, ensuring that your production line operates with the highest efficiency and lowest cost.

We are committed to providing customers with high-quality and versatile condensers to keep your equipment in optimal working condition. Next, let’s take a look at what machines are needed to produce condensers

1, fin make machine

technical parameter

Total power: 8.5 kW

Quantity required: 1 set

Nominal force: 45T

Machine Model Name: CH-45T

Electricity Consumption/Hour: 16

Workers: 2 workers inserted copper tubes into the core

The machine’s Automatic production

Any Safety requirement: Check the lubricating oil on the machine every week

Part Produced per hour: core size 500*800*12mm, production 60-80 per hour

Dimensions: machine 1585*1075*2391/ vacuum 1200*800*1500mm / feeder 1200*1000*1100mm

2, Vertical tube expanding machine

technical parameter

Expansion capacity: 1-6 rows of Φ 9.52

Total power: 22 kW

Power supply: 380V

Working length Size: 300-1200mm

Quantity required: 1 set

Machine Model Name: CH-ZG600

Electricity Consumption/Hour:22

Workers: Small core 1 person/ big core 2 person

Any Safety requirement: Check the lubricating oil on the machine every week

Part Produced per hour: core size 500*800*12mm, production 30-60 per hour

Dimensions: 1500*1400*4500mm

3, Progressive die of the condenser production line

technical parameter

Working Size: 9.52/25.4*22

Dimensions: 700*1200*300

aluminum foil Thickness: 0.04-0.2mm

Quantity required: 1 set

Machine Model Name: CH-MJ12

Electricity Consumption/Hour: 0

Workers: 0

Any Safety requirement: Check the lubricating oil on the machine and Lock the screw every week

Part Produced per hour: follow fin punching machine

Dimensions: 700*1200*300

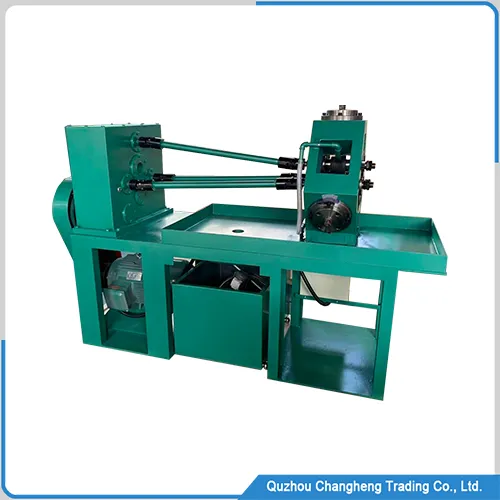

4, Copper tube straightening machine

technical parameter

Total power: 5kw

Dimensions: 3000*1200*800mm

motive power: servo

Automatic cut off No burr

Control system: PLC touchscreen

Quantity required: 1 set

Machine Model Name: CH-G6

Electricity Consumption/Hour: 8

Workers: 1 worker collects copper pipes and Update raw materials

The machine’s Automatic production

Any Safety requirement: Check the lubricating oil on the machine every week

Part Produced per hour: The pipe length is 1200mm / Produced 1000-1200pipes per hour

Dimensions: machine 3000*1200*800mm/ feeder 2200*1200*1800mm / table 2000*1000*800mm

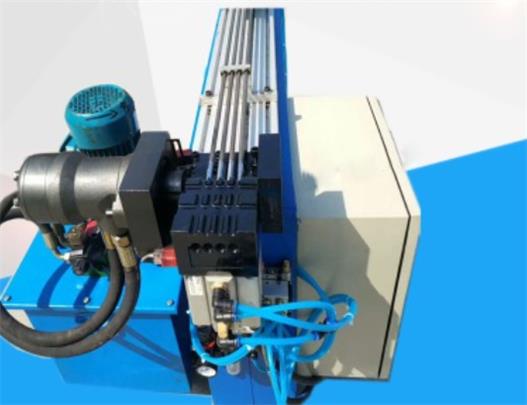

5, Copper tube bending machine

technical parameter

Total power: 2.5 kW

workstation: 4

max Working Size: 9.52/1200mm

Control system: PLC touchscreen

Quantity required: 1 set

Machine Model Name: CH-W4

Electricity Consumption/Hour:3

Workers:1 worker collects copper pipes

The machine’s Automatic production

Any Safety requirement: Check the lubricating oil on the machine every week

Part Produced per hour: The pipe length is 1200mm / Produced 1200-1400pipes per hour

Dimensions: machine 2600*1200*900mm

6, Core bending machine

technical parameter

Total power: 5.5 kw

bend radius: R70-R110

Maximum width:1500mm

motive power: servo

Control system: PLC touchscreen

Quantity required: 1 set

Machine Model Name: CH-W15

Electricity Consumption/Hour: 5.5

Workers: Small core 1 person/ big core 2 person

Any Safety requirement: Check the lubricating oil on the machine every month

Part Produced per hour: core size 500*800*12mm, production 80-100 per hour

Dimensions: machine 3000*2200*1500mm

7, U-type tube bending machine for condenser production line

technical parameter

Dimensions:2200*1500*1200(mm)

Total power: 10 kW

workstation: 4

Power supply: 380V /220V 50Hz

Working Size: customized

Quantity required :1 set

Machine Model Name: CH-W5

Electricity Consumption/Hour:10

Workers:1 worker collects copper pipes and Update raw materials

The machine’s Automatic production

Any Safety requirement: Check the lubricating oil on the machine every week

Part Produced per hour: The pipe length is 1200mm / Produced 1200-1400pipes per hour

Dimensions: machine 2200*1500*1200(mm)

These are all the machines that make home VC condensers production line, If you have anything to add, please contact us

wechat

wechat